Type:

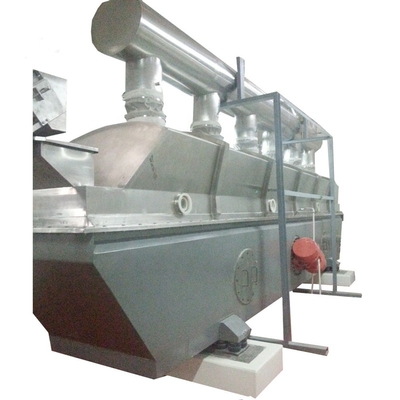

Fluid Bed Drying Equipment

Application:

Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing, Chemicals/food/pharmaceutical Processing

Condition:

New

Voltage:

220-450V, 220v-450v

Power:

15KW

Dimension(L*W*H):

depends on the model

Key Selling Points:

Automatic

Warranty:

3 years

Weight (KG):

5000

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Other, Advertising Company

Showroom Location:

None

Marketing Type:

New Product 2020

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

3 years

Core Components:

Bearing, Pump, Gear, Motor, Gearbox, Other, PLC

Evaporation Capacity(kg/h):

depends on customer's requirement

Heating Method:

Steam /gas/oil/coal/electricaity

Material:

SUS304, SUS304L, SUS316, SUS316L, Ti, SS304/SS316L/Ti

Heating source:

Gas Coal Oil Electric Biomess

Installation:

Engineer Oversea Installation

Raw material:

granule/powder shape

Feature:

High Efficiency Low Cost

Model:

ZLG

MOQ:

1set

After-sales Service Provided:

Field maintenance and repair service

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!